PR9 / PM9 Series Bending Machine

Overview

- Electric and hydraulic system synchronization ensure high accuracy and positioning repeatability.

- Dynamic servo motor precisely controls oil pressure for improved accuracy of the sliding block. *PR9

- Increased cylinder stroke offers more options for tools.

Hydraulic System

Integrated hydraulic system reduces piping connections, eliminates oil leakage and improves stability. Reduced noise and extended service life.

Clamping

Quick clamping can be made based on customers requirements to reduce work load and improve productivity.

Synchronization

The electric-hydraulic servo system controls the synchronization of both cylinders. The closed loop system with a magnetic displacement sensor ensures high synchronization accuracy and high positioning repeatability.

Front Support Device

Fixed front support reduces labor intensity and improves production efficiency.

Compensation

The hydraulic crowning compensation eliminates the effects of of ram deformation.

C Type Throat Compensation Device

Installed at the bottom of the throat of the machine tool, this device is connected to the magnetic gate ruller which improves measurment precision.

Options

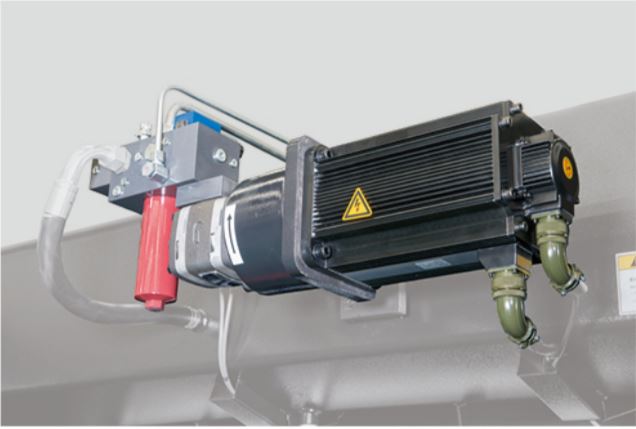

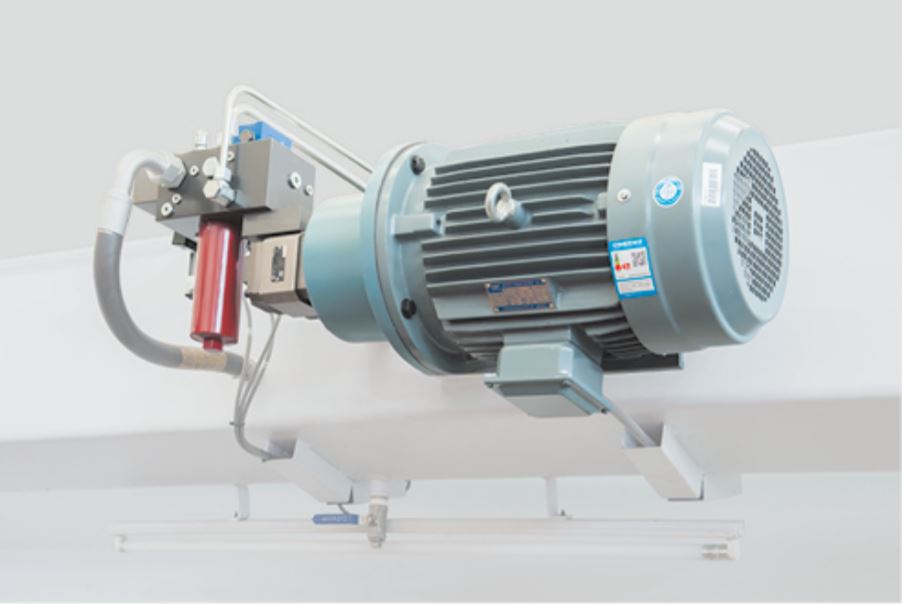

Optional Hydraulic Pump Servo Motor

- Up to 40% increase in energy efficiency

- 7% to 20% increase in sliding ram efficiency

- Oil temperature reduction by up to 20°C

Dual – Side Quick Clip

Movable Front Support Device

Safety Curtain

Automatic Clamping

Mechanical Compensation Device

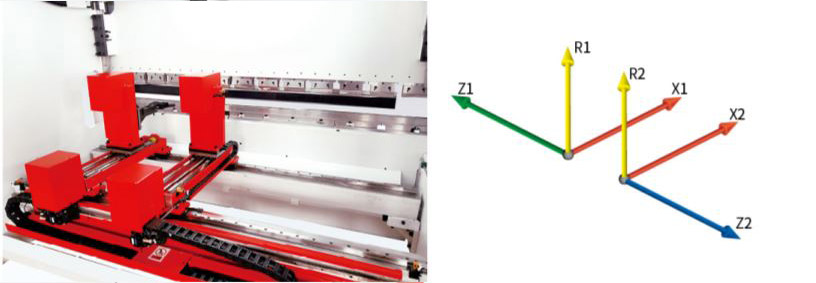

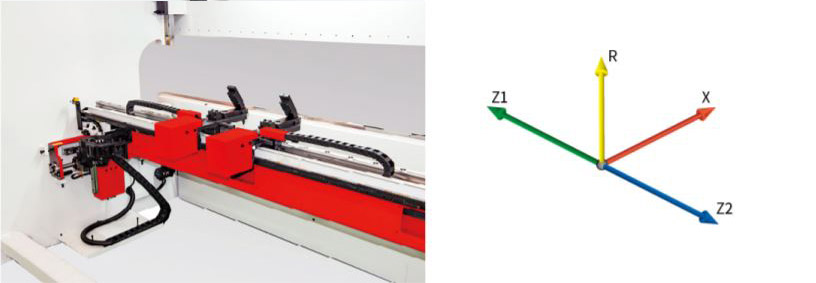

Backgauge

Large lead ballscrew and linear guideways ensure high positioning accuracy and allows bending parts at any angle. Backgauge system can be expanded from 1 up to 6 axis.

CNC Systems

D53T System

- High resolution 10” full color LCD

- PCT toughened glass touch-screen

- 1GB internal storage

- Supports tabular programming

D66T System

- High resolution 17” TFT color display

- USB interfacing

- 1GB internal storage

- 3D visualization in production mode

T-3500T System

- Collision detection

- Bending step auto calculation

- Bending simulation

- 1GB internal storage

TJS-90T System

- 19″ TFT/LCD touch screen

- 4GB RAM ; 64GB SSD storage

- Supports remote control

- Multiple programming options

Technical Data (PR9)

| Main Specitication | Unit | 60T | 100T | 150T | 225T | ||||

| Model | PR9 060/2550 | PR9 100/3100 | PR9 100/4100 | PR9 150/3100 | PR9 150/4100 | PR9 225/3100 | PR9 225/4100 | ||

| Bending Force | kN | 600 | 1000 | 1000 | 1500 | 1500 | 2250 | 2250 | |

| Bending Lenth | mm | 2050 | 3100 | 4100 | 3100 | 4100 | 3100 | 4100 | |

| Column Distance | mm | 2150 | 2700 | 3700 | 2700 | 3700 | 2700 | 3700 | |

| Throat Depth | mm | 350 | 420 | 420 | 420 | 420 | 420 | 420 | |

| Stroke of Ram | mm | 215 | 265 | 365 | 265 | 265 | 265 | 265 | |

| Closed Height | mm | 530 | 530 | 530 | 530 | 530 | 530 | 530 | |

|

Speed

|

Approaching | mm/s | 200 | 330 | 200 | 180 | 180 | 160 | 170 |

| Working | mm/s | 18 | 17 | 13 | 11 | 11 | 10 | 10 | |

| Return | mm/s | 200 | 220 | 150 | 150 | 150 | 140 | 140 | |

| Main Motor Power | kW | 7.5 | 15 | 11 | 15 | 15 | 22 | 22 | |

| Oil Tank Capacity | L | 300 | 350 | 500 | 400 | 600 | 400 | 550 | |

|

Backgauge

|

Precision | mm | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 |

| Stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Speed | mm/s | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Power | kW | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

|

Dimension

|

L | mm | 3400 | 3450 | 4450 | 3470 | 4470 | 3490 | 4490 |

| W | mm | 1400 | 1600 | 1600 | 1720 | 1720 | 1960 | 1960 | |

| H | mm | 2510 | 2700 | 2710 | 2750 | 2710 | 2800 | 2800 | |

Technical Data (PM9)

| Main Specitication | Unit | 60T | 100T | 150T | 225T | ||

| Model | PM9 060/2250 | PM9 100/3100 | PM9 150/3100 | PM9 150/4100 | PM9 225/3100 | ||

| Bending Force | kN | 600 | 1000 | 1500 | 1500 | 2250 | |

| Bending Lenth | mm | 2250 | 3100 | 3100 | 4100 | 3100 | |

| Column Distance | mm | 2150 | 2700 | 2700 | 3700 | 3700 | |

| Throat Depth | mm | 350 | 420 | 420 | 420 | 420 | |

| Stroke of Ram | mm | 215 | 265 | 265 | 265 | 265 | |

| Closed Height | mm | 530 | 530 | 530 | 530 | 530 | |

|

Speed

|

Approaching | mm/s | 200 | 250 | 180 | 180 | 160 |

| Working | mm/s | 20 | 20 | 14 | 14 | 12 | |

| Return | mm/s | 200 | 250 | 180 | 180 | 160 | |

| Main Motor Power | kW | 5 | 13.2 | 13.2 | 13.2 | 16.7 | |

| Oil Tank Capacity | L | 300 | 350 | 400 | 600 | 400 | |

|

Backgauge

|

Precision | mm | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 |

| Stroke | mm | 500 | 500 | 500 | 500 | 500 | |

| Speed | mm/s | 400 | 400 | 400 | 400 | 400 | |

| Power | kW | 1 | 1.5 | 1.5 | 1.5 | 1.5 | |

|

Dimension

|

L | mm | 3400 | 3450 | 3470 | 4470 | 3490 |

| W | mm | 1400 | 1600 | 1720 | 1720 | 1960 | |

| H | mm | 2550 | 2700 | 2750 | 2750 | 2800 | |

Custom Tandem Machines

Bending machines can be customized in tandem configuration for simultaneous operation and bending of parts up to 12m in length. Machines can work both in tandem and individual configurations.

For inquiry and additional information contact HT Solutions local sales representatives from Lithuania, Latvia or Estonia.

LATVIA

Contact Us