MA 3 Axis CNC Bus Bar Milling Unit

Overview

- Two way processing copper arc angle, no need for manual programming.

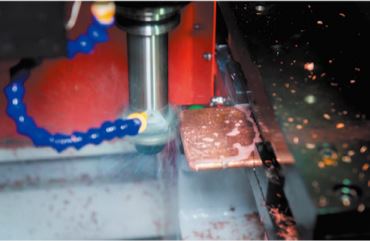

- Variable frequency spindle moto 0 – 3500 speed adjustment, equipped with automatic chip spray system, high milling finish.

- Siemens 8080 CNC system with closed-loop detection and error correction to eliminate processing deviation and workpiece scrapping caused by signal interference in PLC open-loop operation.

Processing of the Spindle

Variable frequency spindle motor with automatic chip spray system and high milling finish.

High Accuracy Processing

High level finish and multiple bending radiuses

Siemens 8080 CNC System

Closed loop detection and error correction.

Technical Data

| Specification | Unit | ??? | |

|

Spindle

|

Taper Hole of Spindle | / | BT40 |

| Total Power | kW | 10 | |

| Spindle Motor Power | kW |

4 (variable frequency)

|

|

| Max. Speed | r/min | 3500 | |

| Tool Changing Mode | / | Pneumatic | |

|

Accuracy

|

Positioning | mm | ±0.03 |

| Repositioning | mm | ±0.01 | |

|

Stroke

|

Bus Bar Length Direction (X) | mm | 200 |

| Bus Bar Width Direction (Y) | mm | 220 | |

| Upward and Downward Direction of the Tool (Z) | mm | 100 | |

|

Processing Range

|

Thickness | mm | 3 – 12 |

| Width | mm | 20 – 140 | |

| Length (Min. Length) | mm | 150 | |

| System | CNC System | / | Siemens 8080 |

For inquiry and additional information contact HT Solutions local sales representatives from Lithuania, Latvia or Estonia.

LATVIA

Contact Us