MB40 Series CNC Bus Bar Bending Unit

Overview

- Servo motor hydraulic system offers better energy saving, high efficiency and lower noise.

- With the high precision displacement measurment system it is possible to maintain accuracy within ±0.2° to meet high precision processing requriements.

- The bending push rod is operated with a servo motor with adjustable speed from 0 to 13 mm/s with a top reversing speed of 50 mm/s.

Bending Force

Using servo motor as bending power source it is more energy saving than a regular motor and offers higher efficienc and bending accuracy.

High Precision Electronic Angle Measuring Device

The high precision electronic measuring device can detect the bending angle of the parts being processed quickly and accurately – in realtime to ensure the requirements of high precision part processing.

CNC System

German Beckhoff CNC systems offer reliability, stable performance, fast response speed and high memory capacity. Combined with automatic programming software developed independently by JFY, it can realize the automatic expansion of the bending workpiece and automatically calculate the expansion length of the busbar according to the standard bending middle layer.

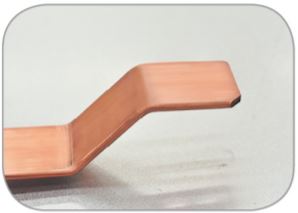

Vertical Bending

Horizontal Bending

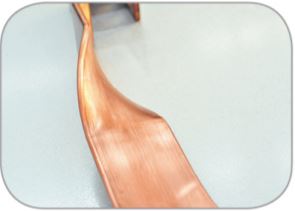

Twist Bending

U Bending

Technical Data

| Specification | Unit | ??? |

| Max. Punch Force | KN | 400 |

| Main Drive | Servo | |

| Bending Accuracy | ° | ±0.2° |

| Max. Bending Angle | ° | 95° |

| Approaching Speed | mm/s |

0 – 13 adjustable

|

| Quick Return Speed | mm/s | 50 |

| Max. Working Stroke | mm | 200 |

| Return Stroke | mm |

0 – 200 adjustable

|

| Total Power | mm | 2000 |

| Max. Vertical Bending Size | kW | 7 |

| U Bending Internal Width (Option) | mm |

200 x 15 (W x T)

|

| Max. Horizontal Bending Size (Option) | mm |

125 x 10 (W x T)

|

| Outline | mm |

4300 x 2000 x 1690

|

For inquiry and additional information contact HT Solutions local sales representatives from Lithuania, Latvia or Estonia.

LATVIA

Contact Us