MP50 Series Bus Bar Punching Machine

Overview

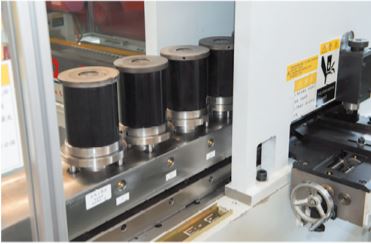

Linear Tool Station

Upper and lower tool libraries adopt a linear structure making tool changing simple and fast. Two toolset options available 6 punching tools + 1 cut tool or 7 punching tools and 1 cut tool.

Hydraulic System

Acording to the working characteristics of bus bar punching and cutting machine the special hydraulic system features low noise and fast punching.

Beckhoff CNC System

Beckhoff industrial system combined with advanced bus bar processing software developed by JFY with high stability as one of the main targets, can complete automatic programming, tool library management, path optimization as well as other auxilary functions.

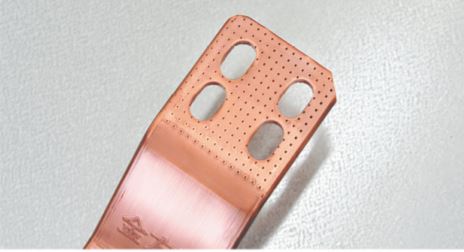

Edging, Marking, Oblong and Radius Edging

Lettering

Deburring

Technical Data

| Specification | Unit | MP50 |

| Max. Punch Force | kN | 500+400 |

| X/Y axis Max.Positioning Speed | mm/min | 80 |

| X axis Stroke | mm | 1000 |

| Y axis stroke | mm | 1700 |

| V axis stroke | mm | 1700 |

| Max. Punch Hit | hpm | 400 |

| Stations | – | 120 |

| Hole Accuracy | mm | 6+1+1 |

| Max. Sheet Thickness | mm |

Copper 15 ; Steel 10

|

| Processing Sheet Size | mm | 6000×200 |

| Max. Punch diameter per Time | mm | 32 |

| Hydraulic stroke | mm |

60 (500kN) + 300 (400kN)

|

| Max. Cutting Width per Time | mm^2 | Copper 200 |

| Max. Marking Size per Time | mm | 160×80 |

| CNC System | BECKHOFF | |

| Max. Hydraulic Force | bar | 270 |

| Total Power | kW | 25 |

| Dimensions | mm |

8500x5000x1600

|

For inquiry and additional information contact HT Solutions local sales representatives from Lithuania, Latvia or Estonia.

LATVIA

Contact Us