MTE Series Punching Machine

Overview

- Enlarged space between turrets

- 38 tool stations

- Follow-up worktable decreases moving resistance and part scratching

- Gear rack drive increases speed and efficiency

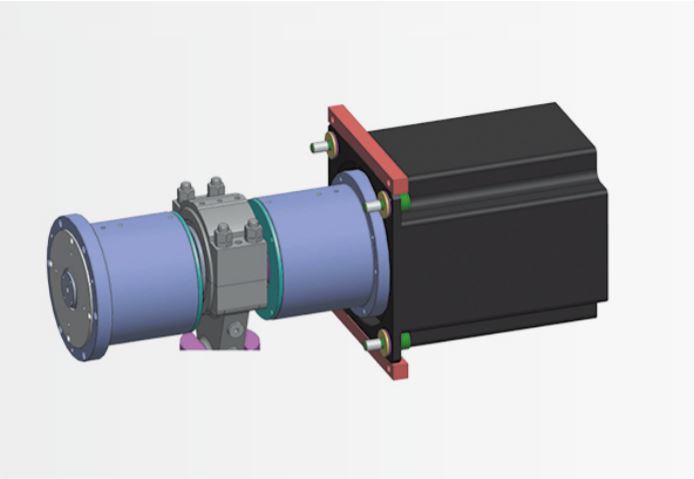

Single Motor Dynamic System

Single motor driving system for high reliability.

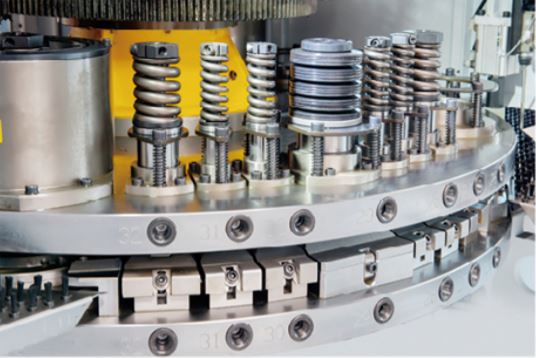

38 Work Stations

Movable Worktable

Reduced noise and vibration

FANUC OI-PF

Quick Tool Clamping

Punching tools are held in place with a single bolt, which allows quick and efficient tool maintenance. (DMT ; MTF ; MT Series)

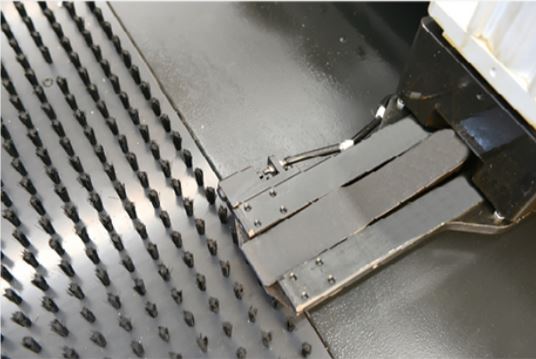

Anti – Strip Alarm

Clamps will auto induct and send out an alarm in case sheets are stripped during punching or not in position while loading. (DMT ; MTE ; MT ; HVT Series)

Sheet Anti – Deformation Alarm

The machine can sense sheet deformation during punching and send out an alarm and perform an emergency stop to prevent damage to the workpiece and machine ( DMT ; MTE ; MT ; HVT Series).

Turret Processing

The turret is processed in pairs to ensure coaxiality of the punch and die which prolongs service life of tooling and improves precision.

Mixed Worktable

Bush and ball mixed worktable reduces noise, vibration and protects the surface of the sheet. (Adapt for sheets above 3 mm).

Technical Data

| Specification | Unit | MTE-3018 |

| Punch Force | kN | 300 |

|

Max. Sheet Size*

|

mm

|

1250×5000 |

| 1500×5000 | ||

| Max. Sheet Thickness | mm | 3.2 |

| Max. Punch Stroke | mm | 40 |

| Max. Punch Diameter per Once | mm | 88.9 |

| Stations | No. | 38 |

| No. of Auto Index | No. | 2 |

| Hole Accuracy | mm | ±0.10 |

|

Max. Sheet Moving Speed

|

X axis m/min | 100 |

| Y axis m/min | 80 | |

| Max. Punch Hits at 1 mm pace & 4 mm stroke | hpm | 820 |

| Max. Punch Hits at 25 mm pace & 4 mm stroke | hpm | 450 |

| Turret Rotation Speed | rpm | 30 |

| CNC System | FANUC | |

| Controlling Axis | No. | 5 |

|

Outline Dimensions

|

mm

|

5340x5530x2360

|

|

5840x5530x2360

|

||

For inquiry and additional information contact HT Solutions local sales representatives from Lithuania, Latvia or Estonia.

LATVIA

Contact Us